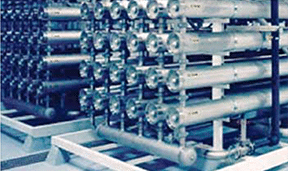

Reverse Osmosis Water Treatment

Biological fouling of reverse osmosis is a common problem leading to reduced efficiency and reduced membrane life.

CleanOxide Liquid 75 is pure Chlorine dioxide which is a highly effective biocide ideal for use in reverse osmosis systems. CleanOxide Chlorine Dioxide has all the important regulatory approvals in Australia and overseas to be used in water treatment and food processing.

Many strategies have been developed in an effort to control biofouling of Reverse Osmosis membranes including the use of sodium hypochlorite, non-oxidising biocides, heat and pH swings.

Controlling the presence of food sources in the feed water and other good housekeeping practices also contribute to controlling the build up of biological contamination on the membrane.

Oxidising biocides such as hydrogen peroxide and chloramines have also found some limited use for aggressive cleaning of Reverse Osmosis membranes when other treatments have failed. Special care is required with these oxidising agents to ensure that no iron or manganese is present in the feed water as the presence of these elements can result in membrane damage.

Free chlorine is known to damage Reverse Osmosis membranes and this has precluded the use of chlorine gas in the feedwater for Reverse Osmosis systems.

Conventional methods of generating chlorine dioxide are accompanied by the production of small amounts of free chlorine which has limited the use of chlorine dioxide for cleaning Reverse Osmosis membrane systems in the past despite the overwhelming advantages of chlorine dioxide.

Effectively eliminate harmful organisms with CleanOxide

When dosed into the reverse osmosis water treatment system at the recommended rate, CleanOxide will control bacteria, fungi, viruses, algae and biofilm. Higher rates will allow the control of micro-organisms on hard surfaces contacted by the irrigation spray such as workbenches, pots and glass in greenhouses.